Mumbai’s construction boom has long come with a costly by-product: rubble and mixed debris piling up on open plots and roadside corners, adding to dust and choking scarce urban space. The Brihanmumbai Municipal Corporation (BMC) tackled this head-on by pairing a citizen-friendly intake system-Debris-on-Call via toll-free numbers and the MyBMC app-with city-scale processing hubs. Requests are geo-tagged, small quantities (up to 500 kg) are collected free to discourage illegal dumping, and material is routed to dedicated plants for recycling rather than to landfills. The western hub at Kokanipada, Dahisar was the first of its kind in the city, designed for ~600 tonnes per day; an eastern hub helps distribute flows across Mumbai. In effect, BMC reframed debris as a managed resource with a clear path from doorstep pickup to reuse.

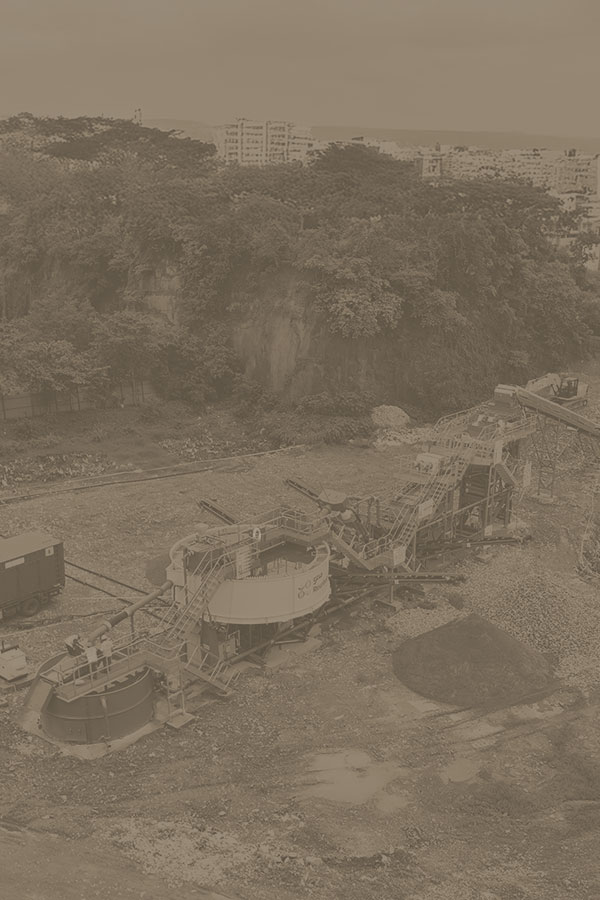

At Dahisar, the facility is operated by Antony Waste, a listed municipal services company. The site runs a modular wet-processing line configured to handle highly variable, often contaminated C&D feed-concrete, brick, stone, soil with incidental plastics and mud. The line follows a classical liberation-then-grading approach: primary reception and scalping remove oversize and obvious contaminants; intensive scrubbing breaks cementitious coatings and clay bonds; wet sizing and density separation recover clean aggregates of two sizes and two sand fractions (concrete and plaster); and a water-management loop thickens and recycles process water to minimize draw. The installed train at Dahisar is CFlo’s Reurban D5100, selected for its compact footprint, fast deployment, and ability to maintain product consistency despite mixed urban feed.

Technically, the value lies in liberation efficiency and fines control. Urban debris often arrives with adhered mortar and variable moisture; without robust scrubbing energy and controlled hydraulics, valuable fines either remain locked in aggregates or

wash away as sludge. The CFlo Reurban D5100 wet processing system configuration addresses this by coupling high-energy scrubbing with calibrated laminar separations, maintaining cut-point stability as feed changes. Downstream sand recovery uses dewatering and classification to produce repeatable gradations suitable for non-structural civic works. The outcome is a steady slate of recycled products: graded aggregates for sub-base and blocks, and sand-like fines for pavers, kerbs, and other urban elements.

Operationally, the plant’s effectiveness is multiplied by the Debris-on-Call front end. Geo-tagging enables route planning, even distribution between the west and east hubs, and better capacity utilization. The free threshold for small loads increases compliance from households and minor contractors, reducing street-side dumping and the secondary dust it creates. Because material arrives with source data, the operator can tune the process in near-real time-adjusting scrub intensity and classification set-points against observed variability in the catchment.

The environmental dividend is twofold. First, landfill diversion: thousands of tonnes each month are converted into inputs for city projects rather than buried. Second, air-quality co-benefits: structured collection and rapid processing reduce open piles that contribute to resuspended dust. Water recycling within the plant further limits the footprint; thickening and closed-loop reuse keep liquid discharge low, a key constraint for dense urban parcels.

Economically, the model closes a municipal material loop. The city’s works departments and local manufacturers gain predictable recycled inputs, while the operator monetizes graded products instead of paying for disposal. For citizens, the service turns a compliance headache into a scheduled pickup; for contractors, it offers a clear, lawful channel with transparent costs at higher volumes. Importantly, the system normalizes recycled aggregates in day-to-day public works-arguably the strongest market signal for circular construction materials.

CFlo’s role at Dahisar is deliberately enabling rather than headline-seeking. The Reurban D5100 provides the process backbone-scrubbing energy, classification control, and water stewardship-inside a footprint that fits Mumbai’s constraints. But the broader success belongs to the BMC program design and the city’s operating partner: a governance and logistics blueprint that many Indian metros can adapt. Technology without intake discipline becomes a stranded asset; intake without robust processing floods landfills. Dahisar works because both sides of the system were built together.

As Mumbai scales its twin-hub model, the lesson for other cities is clear: start with citizen access and data (requests, geo-tags, thresholds), pair it with an advanced modular wet processing system that tolerates feed variability, and lock in end-uses through municipal procurement. With those elements aligned, C&D debris shifts from an urban nuisance to a reliable, specification-driven resource-one truckload, one recycled paver block at a time.

At Antony Waste, our commitment to building a sustainable, waste-free future has led us to constantly adopt forward-looking technologies. The commissioning of the Reurban D5100 C&D waste recycling plant, developed and delivered by CFlo, marks a significant milestone in this journey.

With a processing capacity of 600 tonnes per day, this state-of-the-art plant is reshaping the way Mumbai handles construction and demolition waste. What was once a growing burden on our landfills, is now being transformed into high-quality recycled sand and aggregates. CFlo's eco-friendly technology, with low power consumption and up to 95% water recycling, exemplifies the kind of sustainable innovation our cities urgently need.

We are extremely pleased with the plant's quality, performance, and the unwavering support of the CFlo team throughout the journey. This partnership is more than just technology - it’s a shared vision to create circular economies, reduce urban pollution, and move towards cleaner, more resilient cities.

Mumbai’s Debris-on-Call shows what happens when good policy meets the right process backbone. Our Reurban D5100 at Dahisar was engineered to fit the city’s constraints-tight plots, variable feed, strict water control-but the real catalyst is BMC’s intake design and Antony Waste’s disciplined operations. Together they turn rubble into reliable inputs for public works, proving circular materials can be mainstream in Indian cities.