We work with the largest glass manufacturers to optimize their glass production processes. One of the most common applications for silica sand is in glass production – we manufacture the full range of equipment required on a glass sand processing plant. The modular nature of our equipment ensures:

There is not one specification for glass sand as a result of the many different types of glass that can be produced. Each glass has different chemical and physical properties which require the use of different glass sand. Most of the commercial glass in everyday use is soda-lime-silica glass, which includes:

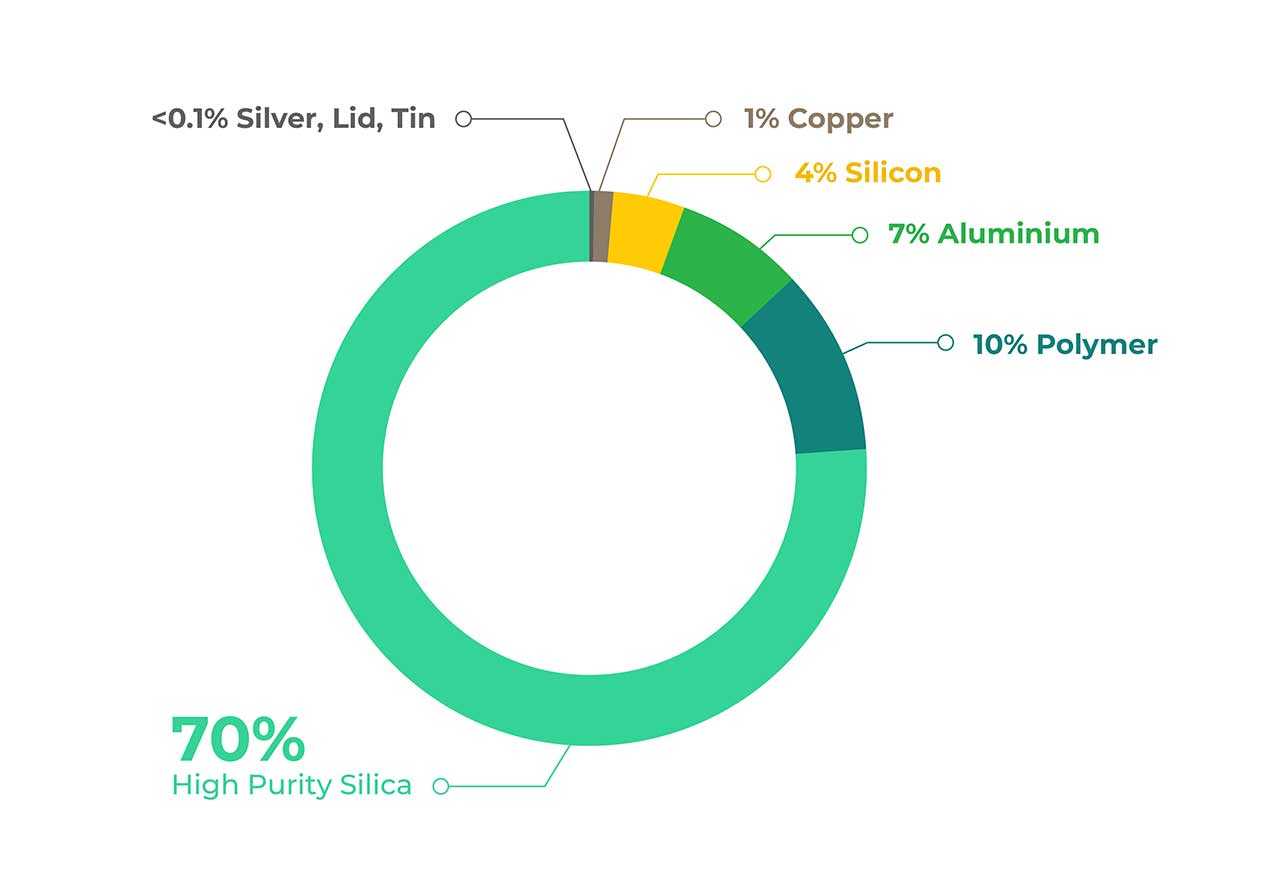

These types of glass contain between 70% and 74% silicon dioxide – the ultimate source of which is silica sand. The production of these specialist silica sands, particularly Low-Iron Glass Silica Sand for Solar Photovoltaic Panels, requires our specialist beneficiation and leaching equipment. This complex process will first involve a detailed analysis of your feed material both in terms of the particle size distribution (PSD) and the chemical properties of your silica sand.

Following this analysis and an understanding of the exact physical and chemical properties you require from your glass sand, we will design and custom-build a low-iron glass silica sand processing plant which typically includes the following equipment from our range: