On our 16th anniversary, we added another feather to the cap with our key contribution to the construction of India’s largest Greenfield route alignment- Samruddhi Mahamarg Expressway

India will soon witness the inauguration of its biggest expressway project- Samruddhi Mahamarg Expressway, officially known as Hindu Hrudaysamrat Balasaheb Thackeray Maharashtra Samruddhi Mahamarg.

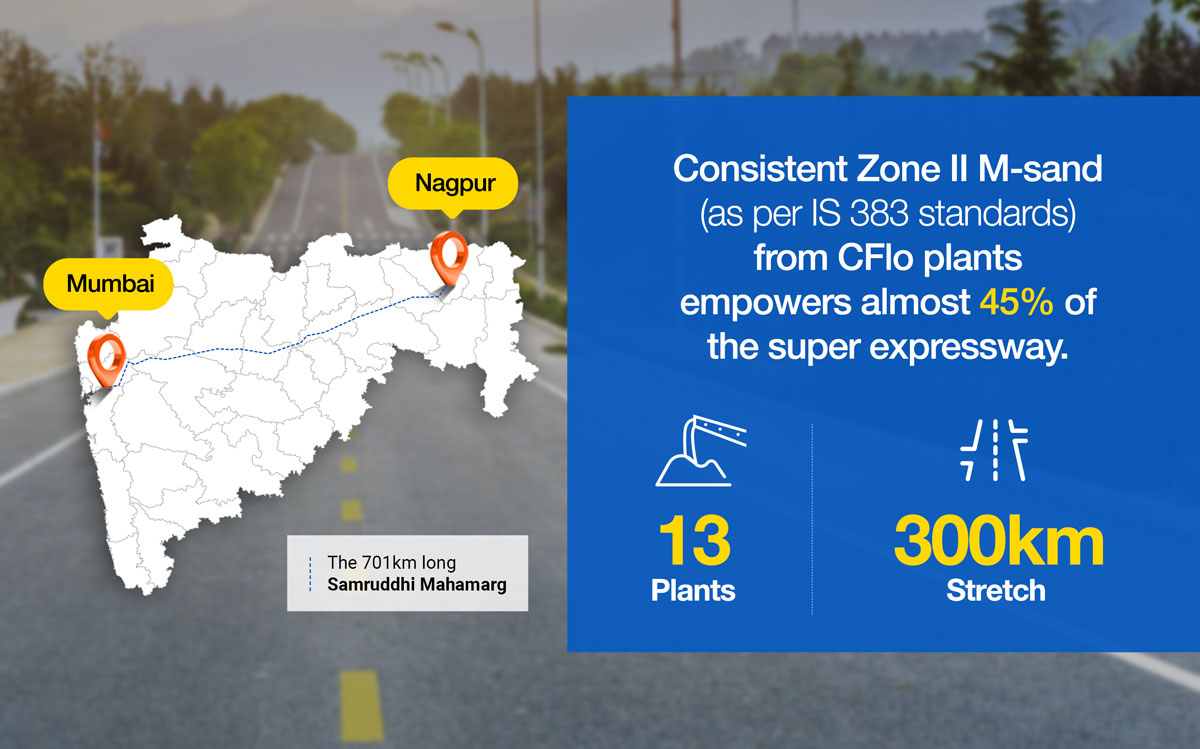

The expressway will link Mumbai, the financial capital of India, to Nagpur, the major hub of Vidarbha Region, and reduce the commute time from 14-15 hours to 8-9 hours. This is considered to be the largest and most ambitious road project in Maharashtra till date.

In view of the project’s enormity i.e., spanning 701 km, it required around 43.3 Lakh Tonne of sand.We as the market leader of the wet processing equipment industry came to aid this critical project.The company in its sixteen years of existence, has created a sand production capacity of 56 million tons per annum with its machines’ operating time of 3000 hours each year. We have created a dominance in the M-sand market with 5 percent of total sand capacity in India, making us one of the largest contributors to the sand industry whose volume requirement stands at 1 billion tons per annum. Thus, reducing the consumption of river sand in India.

The Nagpur-Mumbai expressway passes through ten districts – Nagpur, Wardha, Amravati, Washim, Buldhana, Aurangabad, Jalna, Ahmednagar, Nashik and Thane covering 701 km and 16 packages. The project consists of 50 plus flyovers, 24 plus interchanges, more than 5 tunnels, 400 plus vehicular, and over 300 pedestrian underpasses. Almost 45% of the expressway has been constructed with the sand produced by our plants.

As on date, a total of 13 plants have already been commissioned by us, involving most of the frontline contractors of the construction industry. This includes Afcons Infrastructure Ltd, Dilip Buildcon Ltd, NCC Limited, Navyuga Engineering Company Ltd, Raj Infrastructure Development (India) Private Limited & Roadway Solutions India Infra Ltd. (sub-contractor for Reliance Infra).

Availability of river sand being a major issue in Maharashtra, the construction of this expressway by MSRDC (Maharashtra State Road Development Corporation) demanded a continuous supply of IS 383 grade M-Sand. This is when we flung into action with the goal of providing comprehensive sand solutions and establishing a sustainable and scalable sand resource for the project. In need of an economical, ecologically sound and quality-controlled supply of M-sand, we were the first sand washing company that occurred to the contractor on commencement of the project.

Combo X70, from the flagship Combo platform, was the most sought-after wet sand processing equipment for this colossal project. It is equipped for feeding, grading, dewatering, water recycling, conveying and sludge handling, all in one machine. The ambitious plant has zero liquid discharge and 95% water recycling solution with minimal maintenance to process an accurate cut point of 75 microns of fine particles.The patented Hydrocyclone and thickener combo technology ensures consistent production of M-sand quality as per IS Standard (Zone I-IV). In line with the basic environmental requirement for this project, Combo X70 guarantees zero waste and controlled silt production which places it ahead of its competitors. Given the significant volume requirement for the Expressway, contractors also benefit from the high ROI afforded by Combo X70.