With the severe space constraint, an ever increasing population and diminishing natural resources, “Going Green” is the only way of sustainable development. Mining, Manufacturing, Engineering and Construction industry which form the bed rock of any developing economy in the world cannot ignore the concept of “Going Green” specifically when it comes to conservation of energy, water and natural resources through usage of alternative and natural ways of raising resources etc.

Additionally protection of environment through adoption of appropriate technology is one of the main issues today in industrial practises.

The complexity of modern day concrete constructions coupled with the shortage of river sand due to various legislations against their rampant extraction has led to serious search for alternatives for quite sometimes. A lot of research has been undertaken by the industry and reputed institutes on Manufactured sand produced by different methods as an alternative to river sand. It has been established that particle shape, proper gradation, silt content and absence of deleterious ingredients are some of the major factors for accepting sand for the construction industry. Thus washed Manufactured sand (M-Sand) has now come to be accepted as an adoptable alternative to river sand and these require rocks to be suitably processed through crushing and washing to meet the industry standards. The age old sand production techniques are inaccurate, wasteful and not able meet the stringent demands of the modern day. Furthermore the techniques are not able to meet the pollution control norms because of their inherent limitations. New methods for sand washing have been developed which are versatile, highly efficient and non-polluting.

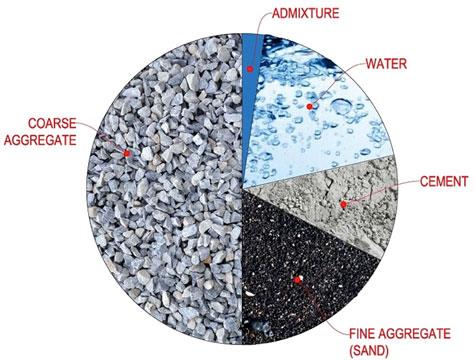

It is well known that concrete is the main engineering material for construction which in turn is a mixture of cement, coarse & fine aggregates and water. It has high flexibility as a construction material as it is formable in the initial stages and becomes hard after setting . It is akin to steel as another construction material.

Cement industry is one of the biggest contributors for greenhouse gases in the world yet the demand for cement is ever increasing because of constantly increasing need for construction for infrastructure as well for domestic dwellings. Hence construction materials which could reduce the requirement of cement would certainly be contributing to green initiatives.

Various types of crushed rock fines have been trying to pass as M-Sand, however they are not suitable for construction, for various reasons. Initially crushed fines were being used as a replacement if river sand was not available but was soon given up because of inconsistent quality, presence of deleterious fines and high level of silt, clay etc. However significant amount of work has been undertaken since then by various laboratories & agencies on the concrete making properties of washed M-Sand and comparing with that of conventional river sand. It has been clearly brought that:

The use of wet processing technology for sand production is an established process across the world. It allows one to increase the efficiency of concrete production by giving a sand product with greatly reduced volumes of material in the minus 74 micron range. When considering the sand fraction, the wet process is required for a number of reasons:

The efficiency of operation and effectiveness of the washing system revolves around the above two processes. Additionally water recovery and recirculation system and sludge handling are other two extremely important aspects which have not found so much importance earlier.

Some of the most common equipment applied in sand washing operations is classifying tanks, sand screws and bucket wheel classifiers.

Classifying tanks accept material from aggregate screening phase and operate using gravity as the means of separation. The material enters a large classification tank which is also fed with a non-stop supply of fresh water to ensure a continuous overflow. The principle of the classifying tank is that the heavier sand particles fall to the bottom of the tank while the very fine particles overflow and are removed. The sand product is then discharged from the classification tank to a sand screw where the product is dewatered and sent to stockpile.

Classification tanks introduce a number of limitations to the process. These systems require large volumes of water in order to ensure the continuous overflow required to remove the excess minus 74 micron material. Classification tanks also require a significant amount of space on site and as a result of their size they can take a long time to install and commission. The use of gravity as the means of separation is also not ideal as it is not an accurate process – meaning that some of the plus 74 micron material report in the fines in order to ensure that the product is free of fines. Additionally the product has high moisture, unsuitable for immediate use in the next process.

Sand screws accept material either directly from the aggregates screening operation or is fed from classification tank, as discussed in 3.1 above , in applications where there is excess fine material in the minus 74 micron range which needs to be removed.

Sand screws employ Archimedes screw principle to achieve dewatering of sand product. The operation of the screw pushes the sand fraction up the elevated chamber while the water and the finer particles pass out through the overflow weir. The overflow weir which is nearer the feed point provides the mechanism for fines removal.

In Bucket wheel classifiers sand slurry is introduced to the bucket wheel near the wheel, where the coarse sand settles and is lifted by the rotating wheel. The rotary bucket elevator scoops up the sand from the tub and on its way to delivery, drains water from sand.

The limited capacity at the feed point of these technologies means that control over the volumes of water required for accurate material classification is very limited. As a result of not being able to use sufficient volumes of water, fines are not efficiently removed. Thus final sand product is not optimized for concrete production – excess fines in sand means increased cement volumes during the concrete production process which adds significant cost to the operation. Additionally quality sand is lost over the overflow weir and is sent to settling ponds or water treatment phase.

There are a number of negative impacts on plant operation as a result of this:

Apart from the typical operational issues with the above technologies of sand washing some of the major drawbacks of the plants using them are:

Picture: Excavator recovers material from large settling ponds used in older design of washing plants

Picture: Material wasted in settling ponds can be reprocessed to recover sand

Taking all of this information into consideration, it is possible to quantify the loss of revenue from sand washing operations employing classifying tanks and sand screws. As an example let us consider a 100-tons-per-hour sand washing plant, operating for 3,000 (10hrs per day for 300 days) hours per year and generating 300,000 tons annual production.

Actual site estimate of the sand loss from sand screws & bucket wheel classifiers could be considered as at least 4-5 percent of production. That equates to 4-5 tons per hour or 12000-15000 tons per year to the settling ponds. Of course, operators tend to re-process this material to recover the material but what also must be factored in here are the costs of this re-processing. Additionally plant shut down would be necessary to clear the ponds for recovering the sand. This is a perpetual problem. This certainly calls for remedial action.

Revolutionary engineering: all in one mobile solution.

The world is increasingly witnessing a strategic shift by quarry and mine operators. They recognise that to gain an edge over their competitor they need to offer the best quality sand to their customers as the modern day builders require sand within very tight specifications. The old technologies are no longer applicable in modern day sand manufacturing as there has been a major shift in construction industry situation. The cultural outlook of the society has also changed towards mining & quarrying activity and it is considered as one biggest polluters of environment. Thus the washing plants have to operate within strict environment friendly way following zero discharge norms with no pollution of the atmosphere either from materials or from noise etc.

To increase return on investment, construction companies are increasingly adopting manufactured sand to reduce cement consumption and faster delivery of projects through quick setting concrete. Hence they prefer to invest in more efficient sand washing systems such as the popular COMBO plants. These new generation of sand washing plants have been developed in Europe in the last two decades with unique design features which has taken note of the above mentioned deficiencies of the existing plants and also addressed the constantly changing requirements of the construction industry to a great extent. Some of the unique features of these are

These come with their own electric control panel and are pre-wired. Water conservation being a major concern in India, the COMBO plants are equipped with water recycling and sludge management system, which recycles 95% of used water.

Mobile washing systems have revolutionised the sand and aggregate washing industry in terms of efficiency, allowing customers to wash even the dirtiest of sands and aggregates thanks to its pinpoint accuracy in silt and clay cut points (usually around 75 to 63 micron).

The unique COMBO plants comprising

into one compact chassis, the COMBO plant is an all-in-one washing solution with a capacity range of up to 200 tonnes per hour.

The water recycling and sludge management unit mounted on the same chassis enables user-friendly water management on site that recirculates 95% of water from the sand washing process immediately for reuse. The water recovery system includes highly efficient water recycling unit along with the revolutionary Easysettle technology for faster settlement of the sludge so that more water could be recovered at the earliest. The technology involves addition of special flocculants to the sludge stream from thickener underflow which modifies the solids in such a way that entrapped water is immediately released and there by the slurry density increases significantly. Additionally the solids now would not absorb water and hence can be left in the open. Thus it enables quick removal of settled solids as they are quite dry and thus make the settling pond availability much higher. The water recovery now is almost 95%. The overall plant availability has increased significantly, higher than 90%, and this well compensates the cost of additional chemicals.

Paying particular attention to quality, performance and resilience, all transfer points, pumps and pipes are rubber-lined for maximum wear resistance, screening media use high wear life PU panels and features a high frequency dewatering screen design. Each machine is developed, made to order and tested at the factory to satisfy every requirement set out by the client.

As may be seen these new age plant & technology

For all quarry and mine operators as well as the construction contractors who wish to optimise business operations, the flexibility of new sand washing equipments and the range of applications available to them are set to revolutionise the industry.

Picture: Clean and efficient COMBO plant site with 95% water recycling and no discharge of wastewater to atmosphere.

Conclusion

Visit the Combo page to know more about the product