Washed Manufactured Sand vs Unwashed VSI Crusher Fines

The construction industry has “by far the biggest ‘sand footprint’ in the world”1, claiming one third of its 40 billion-ton-a-year consumption. With the current surge in construction activity at the global level, and notably in Asia, this consumer trend shows no sign of abating.

As a consequence, there is international recognition that natural sand reserves and the eco systems of which they are a crucial regulating element, need to be maintained.

Indeed, primary sources of natural sand, river beds and deserts are now increasingly being protected by governments that closely monitor sand mining and sanction illegal operators.Often, when unable to mine for natural sand, some operators resort to using unwashed crusher fines to produce cement and mortar at low cost, producing poor to very uneven results.

But it is not a case of ‘either - or’, natural sand or unwashed crusher fines. For those who wish to produce sand at consistent quality and quantity levels, with the option to choose specific grades, materials washing is the simple and accessible solution for their operations.

Manish Madhogaria, Former CFO, CFlo highlights: “The ever-growing need for quality sands, combined with depleting world reserves of natural sand and increasing bans on harvesting, has forced construction companies out of their ‘unwashed’ comfort zone to consider manufactured sands as a means to increase their returns on investment, increase product quality and adaptability, and stay one step ahead of their competitors.

“Whilst unwashed crusher fines continue to be used in operations that require minimal grade specifications and where reduced costs are prioritised over quality, sand and aggregates washing is now widely recognised as the best value-for-money option by those wishing to achieve a high quality product that will guarantee longer-term resistance to erosion of the final construction material.”

Unwashed crusher fines, as a waste material left over from crushed rock, feature a gravel-like surface and are used as trail and car park surfacing as they pack well, as long as subgrade preparation and drainage work has been done. This is on the understanding that the underlying soil is suitable for use of unwashed fines.

However, regardless of the quality of the preparation work, unwashed crusher fines remain vulnerable to wash-outs from rain and all types running water (streams, melting snow etc). Their use is also limited to specific construction operations with unsophisticated needs, such as hiking trails. Even then, the texture of crusher fines, which can be too smooth or too hard, can fail to make the grade for a fully accessible surface. Additives such as lime are then used to help to even out the texture, which in turn creates a new set of difficulties in terms of reaching a balance that will never produce an exact, replicable mixture offering consistency in results.

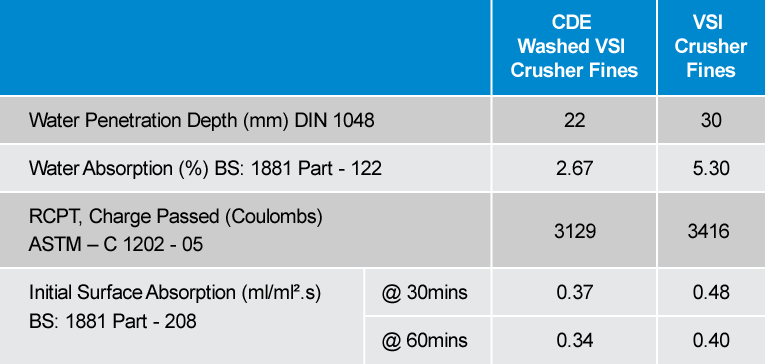

When comparing the physical properties of fine aggregates, figures speak for themselves.

CFlo experts can evidence why using washed sand and aggregates to reduce water penetration makes sense:

A carefully measured combination of cement, sand, gravel (or rock chippings) and water, “concrete is in fact the most used man-made material in the world, with three tons used annually for each man, woman and child. Twice as much concrete is used around the world than the total of all other building materials, including wood, steel, plastic and aluminium. Its superior properties on strength, durability, thermal mass and affordability make it the material of choice for most purposes.2

In a nutshell, concrete is the beating heart of the construction industry: it needs to be strong, versatile and of course value-for-money for constructors who want to maintain their competitive edge. All these requirements are interconnected and when each box is ticked, the operator knows that along with their customer they have mutually benefited from using washed sands.

Strength and versatility: the stronger the concrete, the wider scope of applications it will adapt to.

When choosing materials to mix concrete for their operations, construction companies understand that unwashed crushed fines can inhibit the quality of the final product and need to make a choice based on the type of application they have been working towards and priorities such as product longevity and quality.

Choosing unwashed crushed fines often leads to adding more chemical and mixtures to compensate for poor quality sand. As concrete performance directly depends on the quality of the sand used in the mix, more and more construction companies now choose the safe, quality option of washed sands that are made to their exact specifications.

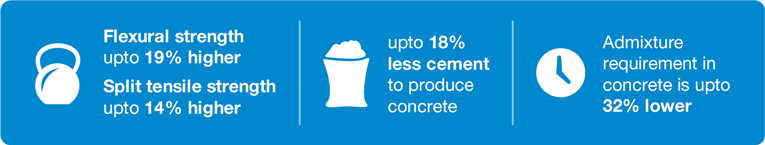

It’s a no-brainer: it has been demonstrated that the use of our sand in the mix will greatly increase your concrete’s compressive strength and therefore workability when compared to VSI crusher fines. In the same vein, levels of flexural and split tensile strength when using our sand have shown to jump ahead of levels achieved by VSI crusher fines by up 19%.

Cost: better sand, better, stronger concrete. Cement is expensive. Indicative of the cost-saving aspect of sand washing, our washed concrete sands compare favourably to unwashed crusher fines when looking at the weight required in the mix proportion. It takes 355 kg/cum of VSI crusher fines to catch up with the result only 300 kg/cum of our washed sand achieves. Former Manish Madhogaria, CFlo highlights: “Our sand and aggregates washing solutions are tailor-made to each client’s budget, circumstances and production needs. Our products are built to last in our own production facilities, adapt to any environment, and require less installation times than products tested at commissioning stage. Many mines and quarries operators who are using our washing products have been able to enhance their offering in terms of grades, value for money, quantities and delivery time. Operators who have switched to our sand-washing have noticed immediate benefits to washing materials in terms of their client offering, predicted profit margins and simple ease of use as our products are built to last and dedicated and efficient customer care protocols are in place. In short, they have not looked back. “We currently work with a number of existing clients who as a result are developing their operations and upgrading their CFlo plants by adding new, more powerful sister plants.”

Mortar, a thick mixture of water, sand and cement, cannot be substituted for concrete (and vice versa) at the risk of serious quality failure in the final product. A substance that needs to be replaced every 25 to 50 years, its longevity makes it unsuitable for structural projects. With a higher ratio of water to bond the mixture together, it is used to glue building materials such as bricks. To be value-for-money, mortar needs to stand the test of time.

As with concrete, mortar mix benefits greatly from incorporating our plaster sand as opposed to unwashed VSI crusher fines. Using washed sand not only increases the quality of the mortar but also significantly reduces costs as you need substantially more plaster sand than you would crusher fines to obtain the same quantity of mortar. Typically, it takes 34% less of our sand than VSI crusher fines to mix good quality concrete.

The average flexural strength is also improved with our sand, boasting 1.8 N/mm² compared to VSI crusher fines’ 0.89 N/mm². Importantly, when it comes to cracking, testing shows that the crusher fine-mortar ring displays uneven texture and various cracks after just 6 hours, when our sand-mortar ring retains an even texture and only starts to show light cracks after 48 hours.

Join the 21st Century’s sand washing revolution.

Sagar Machhindra Chavhan, Vertical Head - Sand & Aggregates, CFlo recaps: “Choosing materials washing is the only solution that makes sense in an industry whose needs for quality construction sands are predicted to grow significantly as major infrastructural projects are being developed across the world. The India construction sector is particularly active and building concrete and mortar operators are already ahead of the curve, many having switched to CFlo washed sands to keep an edge over their competitors. We have been extremely successful in introducing our washed m-sand technology to several countries. In India alone, it is available in over 40 cities”

“By using unwashed VSI crusher fines in your concrete or mortar mix you reduce the quality and strength of the final product and therefore reduce the range of applications to which it can be adapted.

“By using CFlo sand in your concrete or mortar mix, you achieve a high-quality product that necessitates smaller quantities of washed sand that it would of crusher fines, therefore giving your clients a value-for-money option. You also increase your customer offering in terms of quality, texture, strength and adaptability to a wide range of applications.

“To offer your clients value for money whilst giving you competitors a run for their money, now is the time to switch to sand washing!

Source 1: http://www.worldcement.com/special-reports/16062015/Footprints-in-the-sand-829